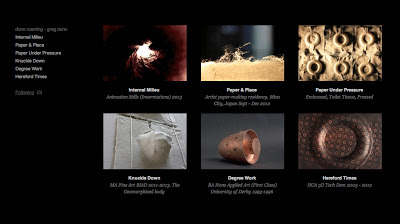

Factory Visit –

April 2013

Upon entering the Brooks England factory, it immediately felt like a ‘family

affair’. Only a thin glazed boundary divided the office and factory spaces, creating

a cohesive feel between office and factory staff. The staff were instantly welcoming and

humorous and I personally couldn't wait to get on with the factory ‘tour’.

The Office Manager, Steve, guided us through the manufacturing process -

‘Goods In’ all the way through to ‘Goods Out’, showing us the raw materials

that make their way through stamping, folding, stretching, bending and

breaking. Brooks utilize materials as

diverse as leather and titanium in the production of their bicycle saddles and

accessories.

The factory space was lofty, airy and bright; probably cold in the wintertime

but on a sunny day in April, this corrugated cathedral to British engineering somehow

shone - the containers of chrome components sparkled through the pulsing commotion

of machinery and blaring radio daze. It

was a surprisingly pleasant place to be, not just because of the inherent

productive activity, but the men and women greeted us with smiles and welcomed

us with warmth. The employees seemed relaxed

about demonstrating their activities to us, they appeared proud, self-assured

in what they were producing. This was an earnest effort – a proud individual

determination and sense of belonging to a whole.

Steve showed us decade’s old machinery, like bulky old iron men,

steadily turning out steadfast parts – turning wire into springs and pressing

plates into cups. The somber edged

economy of the equipment brought forth memories of a richer material past, a

time when brawn succeeded elegance. The

large contraptions, mostly air driven, hissed - loudly driving cogs, cams and

cutting tools; they were metronomic and hypnotic. Being close to the power of the machinery was

slightly disconcerting for us but the calm workers seemed deftly intertwined

with their motorized counter-parts. They

seemed at one with automation, instinctively moving between mechanical movements,

their limbs dancing underneath the tooling.

In another part of the factory, tanned leather (of various colours and

hues) lay upon palettes under skylights; their aroma was distinctive, warm and

pungent. Hide from the U.K. Ireland and

Scandinavia, waiting to be divided, cut, pressed and paired into saddles. Veins were visible, evidence that the material

was once skin, it was once alive - it had housed a beast, witnessed the seasons

and taken on the qualities of its surroundings.

Stamped, soaked and stretched, pushed over brass patterns and the edges

cut away by hand, the saddles then needed time to rest - they were being cured

in rows on racks, now waiting to be numbered, stamped and branded.

Then fixing to the frame. The

formed saddles were fastened by machine and by hand. Employees yielded sharp-nosed customized

hammers, shiny-ended mallets to round down the rivets. Hands were essential here, harmonious hitting

upon the saddle’s surface left the traces of their manipulation in glistening

copper. The maker’s monogram was left behind;

the individuality of the day was left as a coded signature forever.

And the final cut - the saddle chamfer, carried out by the wonderfully

enthusiastic, Eric Murray (pictured above) . Eric executed

the chamfer with humility and purpose, using an old knife, especially sharpened for

the job. Eric and his cohorts seemed to

have a wonderful ability for concentration.

In all the noise and movement of the factory floor, they seemed to possess

attentiveness in the face of incredible distraction. There’s a lesson for us

all there in the modern world of attention deterioration it pays to practice,

to commit to doing one thing really well.

And so to polishing; the black leather saddles, were liquorice-like and

quickly buffed to a regimental sheen; the brown saddles had a conker-like

finish when completed; the resulting surface, beautifully tactile and pleasing

to the touch.

I think we all came away from Brooks feeling proud and privileged to

have been allowed to look around the premises. Those of us who didn't own a

Brooks saddle wanted to buy one; those who did wanted to get away and go

cycling. The whole experience fuelled

our enthusiasm to be involved with the company. It deepened our understanding

of the brand, the products and people who are so lovingly involved with them. Thank you for having us.

Gregory Dunn